I. Muhimmancin Zabar Sark'i da Sark'a Madaidaici

A cikin masana'antar siminti, lif ɗin guga suna da mahimmanci don jigilar kaya masu nauyi, masu ɓarna irin su clinker, limestone, da siminti a tsaye.Zagayen sarƙoƙi da sarƙoƙikai gagarumin damuwa na inji, yin ƙira da samar da ingancin sarrafa mahimmanci don nasarar aiki. Ga dalilin da yasa zabar abubuwan da suka dace da kuma yadda SCIC ke magance wannan:

1. Ƙarfin Ƙarfafawa:Sarkoki da sarkokidole ne ya yi tsayin daka mai tsayi da tasirin girgiza daga ci gaba da motsin guga. Abubuwan da ba su da inganci suna haifar da gazawar kwatsam, haifar da raguwar lokaci, haɗarin aminci, da gyare-gyare masu tsada. Rikon SCIC ga ka'idodin DIN yana tabbatar da cewa samfuranmu sun cika buƙatun ƙarfin da ake buƙata, kamar ƙayyadaddun ƙarfi na 280-300 N/mm².

2. Resistance Wear: Halin abrasive na kayan siminti yana haɓaka lalacewa akan abubuwan haɓakawa. Sarƙoƙin da aka taurare (har zuwa 800 HV) da sarƙaƙƙiya (har zuwa 600 HV) suna ba da tsayin daka don tsayayya da abrasion, yayin da ke riƙe ainihin tauri don hana fashewa. Madaidaicin tsarin carburizing na SCIC yana cimma kauri 10% da ake buƙata da zurfin 5-6% mai inganci, yana tabbatar da aiki na dogon lokaci.

3. Ka'idodin Ka'idoji: Yin biyayya da DIN 764, DIN 766, DIN 745, da DIN 5699 yana tabbatar da cewasarkoki da sarkokihadu da ma'auni na masana'antu don girma, kaddarorin kayan aiki, da aminci. Ƙwarewar SCIC wajen saduwa da waɗannan ƙa'idodi na tabbatar da daidaiton ingancin da aka keɓance don aikace-aikacen masu nauyi.

4. Samar da ingancin sarrafawa: SCIC's ƙwaƙƙwarar ingancin kulawa-daga zaɓin kayan abu zuwa dubawa na ƙarshe-yana rage lahani kuma yana tabbatar da daidaiton girman, taurin, da ƙarfi. Wannan ƙarfin yana rage yuwuwar gazawa a ƙarƙashin matsanancin yanayi na masana'antar siminti.

Zabar damasarkoki da sarkokiyana da mahimmanci ga inganci da amincin masu hawan guga na ku. A SCIC, samfuranmu an tsara su kuma an ƙera su don saduwa da ƙayyadaddun ka'idodin DIN, tabbatar da cewa za su iya tsayayya da nauyi mai nauyi da kayan abrasive na yau da kullun a masana'antar siminti. Tare da ingantaccen kulawar ingancin mu, zaku iya amincewa da cewa sarƙoƙi da sarƙoƙi za su samar da ingantaccen aiki, rage haɗarin gazawar da ba zato ba tsammani da farashin kulawa.

II. Daidaita Tauri da Ƙarfi Lokacin Kerawa

Samun takamaiman takamaiman abokin ciniki (800 HV don sarƙoƙi, 600 HV don sarƙoƙi), kauri carburizing (10% na diamita na haɗin gwiwa), zurfin taurin tasiri mai ƙarfi (550 HV a 5-6% na diamita), da karya ƙarfi (280-300 N / mm²) yana buƙatar daidaiton hankali tsakanin taurin da ƙarfi. Anan ga yadda SCIC ke cim ma wannan ta hanyar zaɓin kayan abu, maganin zafi, da carburizing:

Maɓallai Tsarukan Masana'antu

1. Zabin Abu:An zaɓi manyan ƙarfe-carbon ko gami don iyawar su don amsawa ga carburizing da quenching, suna ba da taurin saman ƙasa da taurin gaske.

2. Karba:Carburizing yana watsa carbon cikin saman karfe don ƙara taurin. Don hanyar haɗin yanar gizo tare da diamita na 20 mm;Zurfin Carburizing: 10% na 20 mm = 2 mm;Ƙunƙarar Ƙarƙashin Ƙarƙashin Ƙarfafa: 5-6% na 20 mm = 1-1.2 mm a 550 HV;Wannan yana haifar da ƙasa mai wuya, mai jurewa lalacewa yayin da ke adana jigon ductile don ɗaukar nauyi mai ƙarfi.

3. Maganin zafi:Quenching: Bayan carburizing, an kashe abubuwan da aka gyara don kulle a cikin taurin saman (800 HV don sarƙoƙi, 600 HV don sarƙoƙi);Tempering: Sarrafa zafin jiki (misali, a 200-250°C) yana daidaita kaddarorin ainihin, yana tabbatar da ƙarfi da ƙarfin da ake buƙata na 280-300 N/mm². Yawan zafin rai yana rage taurin, yayin da rashin zafin rai yana haifar da ɓarna.

4. Dokar daidaitawa: Taurin: Babban taurin saman yana tsayayya da lalacewa daga kayan abrasive;Ƙarfi: Ƙarfi na asali yana hana karyewar ɓarna ƙarƙashin nauyin ɗamara.SCIC tana sarrafa zurfin carburizing da sigogin zafin jiki don guje wa wuce gona da iri yayin saduwa da ƙayyadaddun abokin ciniki.

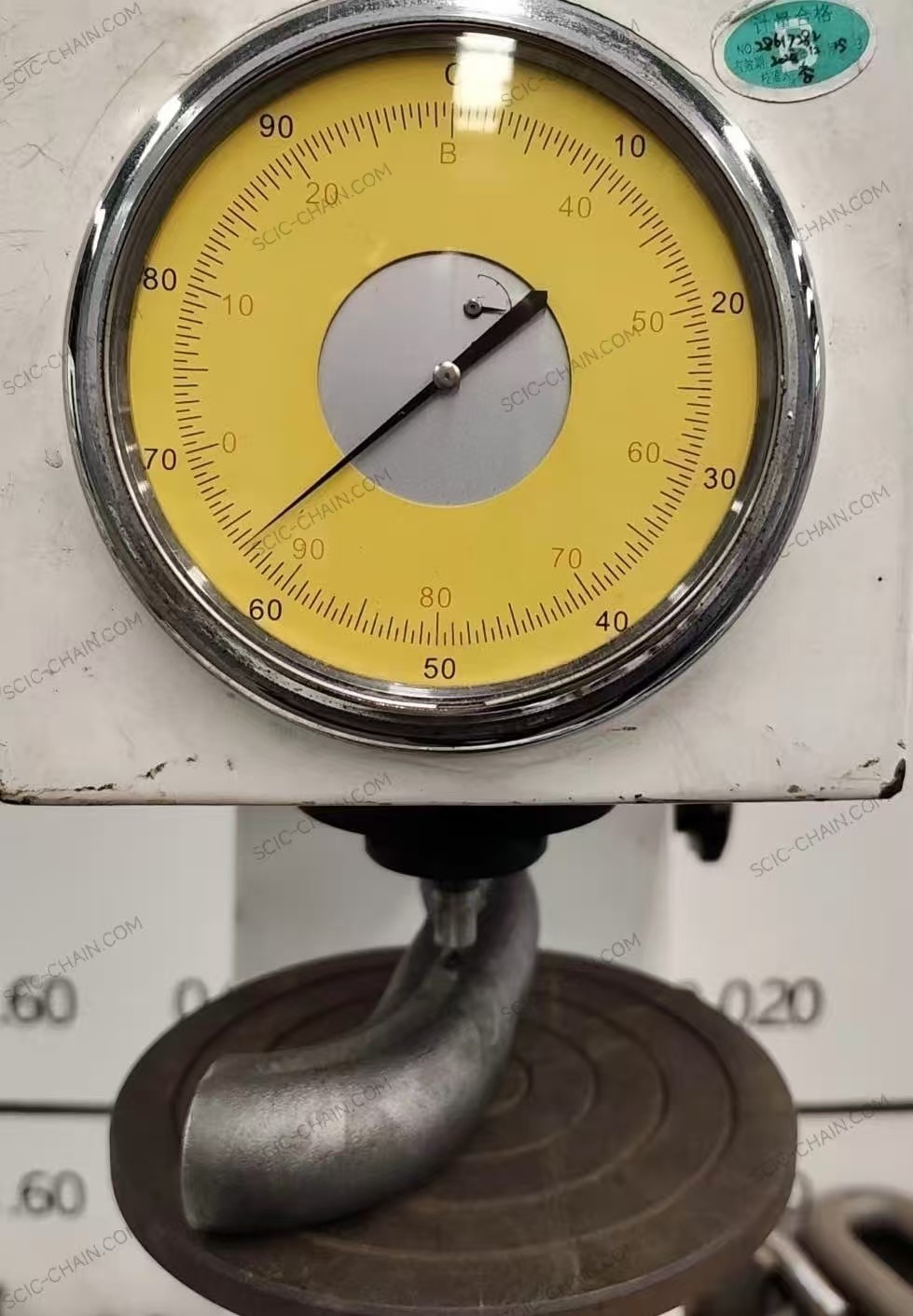

(sarkar mahada tare da high carburized surface taurin)

(sarkar haɗin gwiwa tare da babban taurin saman carburized, bayan karya gwajin ƙarfi)

Tsarin masana'antar mu ana sarrafa shi sosai don cimma daidaiton daidaito tsakanin taurin da ƙarfi. Ta hanyar daidaitaccen carburizing da magani mai zafi, muna tabbatar da cewa musarkoki da sarkokisami ƙasa mai ƙarfi, mai jure lalacewa yayin da ke riƙe da tushe mai tauri don ɗaukar nauyi mai ƙarfi a cikin ayyukanku. Wannan ma'auni yana da mahimmanci don haɓaka tsawon rayuwa da amincin kayan aiki.

III. Tabbatar da Tsawon Rayuwa Ta Hanyar Aiki da Kulawa

Ko da tare dasarƙoƙi masu inganci da sarƙoƙi, aiki mai kyau da kulawa suna da mahimmanci don haɓaka tsawon rayuwa a cikin lif ɗin masana'antar siminti. SCIC tana ba da jagora mai zuwa ga abokan ciniki:

Ka'idojin Kulawa

1. Dubawa akai-akai:Dubasarkoki da sarkokidon alamun lalacewa, kamar elongation (misali,> 2-3% na tsawon asali), nakasawa, ko fashewar saman. Ganowa da wuri yana hana gazawa.

2. Man shafawa:Aiwatar da maɗaukakin zafin jiki, mai mai nauyi don rage gogayya da lalacewa. Lubricate kowane sa'o'in aiki 100-200, ya danganta da yanayi.

3. Kulawa da tashin hankali:Kiyaye mafi kyawun tashin hankali na sarkar don guje wa ɓacin rai mai yawa (wanda ke haifar da juzu'i) ko wuce gona da iri (ƙara lalacewa). Daidaita kowane ƙayyadaddun SCIC.

4. Canjin Kan Kan Lokaci:Sauya abubuwan da aka sawa ko lalacewa nan da nan don hana gazawar lalacewa. Misali, ya kamata a musanya wani gurbatacciyar sarkar da aka yi da wuri.

5. Mafi kyawun Ayyuka:Yi aiki a cikin iyakokin ƙira (misali, guje wa yin lodi fiye da 280-300 N/mm² ƙarfin karyewar ƙarfi) don rage damuwa.

Don haɓaka rayuwar sarƙoƙi da sarƙoƙi, bi waɗannan ayyukan: bincika akai-akai don lalacewa, tabbatar da mai mai kyau, saka idanu sarkar sarƙoƙi, da maye gurbin abubuwan da suka lalace cikin sauri. Ta bin waɗannan jagororin da aiki cikin iyakoki na ƙira, za ku iya tsawaita aminci da inganci na lif ɗin ku.

Nazarin Harka: Tasirin Duniya na Gaskiya

Yanayi:

Wani masana'antar siminti ya fuskanci gazawar sarkar hanyar haɗin gwiwa akai-akai, tare da raguwar sa'o'i 10 a kowane wata saboda sarƙoƙi tare da taurin HV 600 kawai da zurfin carburizing. Wannan ya haifar da tsadar gyare-gyare da asarar samarwa.

Magani:

Masana'antar ta ɗauki sarƙoƙin mahaɗin daɗaɗɗen shari'ar SCIC:

- Siga: 30mm diamita, 800 HV surface taurin, 3mm carburizing zurfin, 1.8mm tasiri taurin a 550 HV, 290 N / mm² karya karfi.

- Kulawa: dubawa na mako-mako, lubrication kowane awa 150, da daidaitawar tashin hankali.

(hanyoyin sarkar tare da ingantaccen zurfin carburizing zuwa diamita na 10%)

IV. Sakamako

1. Downtime: An rage shi da 80% (zuwa 2 hours / watan).

2. Rayuwa: Sarƙoƙi sun kasance watanni 18 (vs. 6 months baya).

3. Tattalin Arziki: Kudin kulawa ya ragu da kashi 50% a shekara.

Wannan yana nuna yadda abubuwan haɗin SCIC masu inganci da jagorar kulawa suna ba da fa'idodi na gaske.

V. Kammalawa

1. Zaɓin Abubuwan Da Ya dace:SCIC's DIN-madaidaitan sarƙoƙi da sarƙoƙi, goyan bayan mafi kyawun ƙira da kula da inganci, tabbatar da aminci da inganci a cikin injinan fa'idar siminti guga.

2. Daidaita Tauri da Ƙarfi: Madaidaicin hanyoyin masana'antunmu sun haɗu da ƙayyadaddun abokin ciniki, ba da juriya da ƙarfin ɗaukar nauyi.

3. Ƙarfafa Rayuwa: Jagoran kulawa na yau da kullum yana tabbatar da aminci na dogon lokaci.

Ta hanyar haɗin gwiwa tare da SCIC, abokan ciniki suna samun damar yin amfani da ƙwararrun sarƙoƙi da sarƙoƙi, waɗanda aka keɓance da buƙatun su, da goyan bayan ingantattun dabaru don haɓaka aiki da rage farashi.

Lokacin aikawa: Afrilu-21-2025