1. Kada a sami skew da lilo lokacin da aka shigar da sprocket a kan shaft. A cikin taron watsawa iri ɗaya, ƙarshen fuskokin sprockets guda biyu ya kamata su kasance cikin jirgi ɗaya. Lokacin da tsakiyar nisa na sprockets ya kasa da 0.5m, da izinin da aka yarda shine 1mm; Lokacin da tsakiyar nisa na sprocket ya wuce 0.5m, abin da aka yarda da shi shine 2mm. Koyaya, ba'a yarda da gogayya a gefen haƙoran sprocket. Idan ƙafafun biyu suna motsawa da yawa, yana da sauƙi don haifar da rabuwar sarkar da saurin lalacewa. Kula da hankali don dubawa da daidaita gyara lokacin maye gurbin sprocket.

2. Idan ya yi tsayi da yawa, za a ƙara yawan amfani da wutar lantarki kuma za a iya sawa a sauƙaƙe; idan yayi sako-sako da sarkar dagawa yana da saukin tsalle da tashi. Ƙunƙarar sarkar ɗagawa shine: ɗagawa ko danna daga tsakiyar sarkar, tsakiyar nisa na sprockets guda biyu shine kusan 2% - 3%.

3. Abubuwan da aka yi amfani da susarkar dagawaba za a iya haɗuwa da wasu sababbin sarƙoƙi ba, in ba haka ba yana da sauƙi don samar da tasiri a cikin watsawa da karya sarkar.

4.Bayan sawa mai tsananisprocket, sabon sprocket da sabon sarkar ya kamata a maye gurbinsu a lokaci guda don tabbatar da meshing mai kyau. Ba zai yiwu a maye gurbin sabon sarka ko sprocket daban ba. In ba haka ba, zai haifar da mummunan meshing da kuma hanzarta lalacewa na sabon sarkar ko sprocket. Bayan an sawa saman haƙoran haƙora zuwa wani ɗan lokaci, ya kamata a juya shi cikin lokaci (yana nufin sprocket tare da daidaitacce). Don tsawaita lokacin amfani.

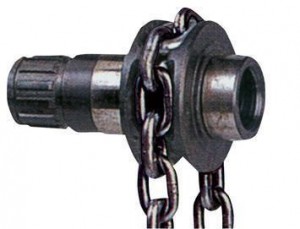

5. Sabuwar sarkar ɗagawa ta yi tsayi da yawa ko kuma an shimfiɗa ta bayan amfani, wanda ke da wahalar daidaitawa. Ana iya cire hanyoyin haɗin sarkar bisa ga halin da ake ciki, amma lambar hanyar haɗin yanar gizon dole ne ta kasance daidai. Ƙimar sarkar za ta ratsa ta baya na sarkar, za a shigar da gunkin kulle a waje, kuma buɗe maɓallin kulle ya kasance a cikin kishiyar juyawa.

6. Ya kamata a cika sarkar ɗagawa da man shafawa a cikin lokaci. Dole ne mai mai mai mai ya shigar da izinin dacewa tsakanin abin nadi da hannun riga na ciki don inganta yanayin aiki da rage lalacewa.

Lokacin aikawa: Yuli-17-2021