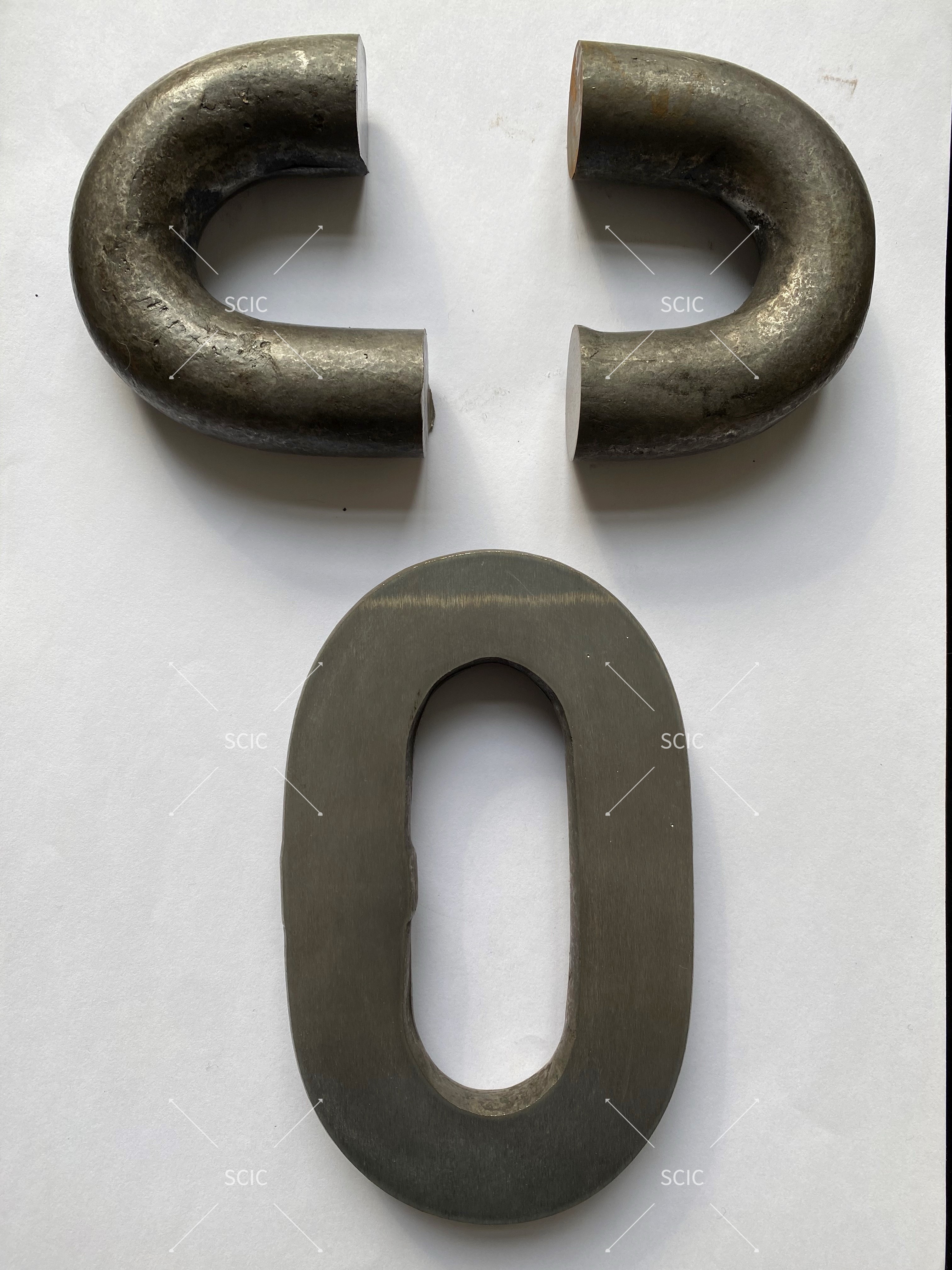

Tsarin jigilar kayayyaki wani bangare ne na masana'antu da yawa, suna ba da hanya don motsi mara nauyi na kayan da kayayyaki.Zagaye mahada karfe sarƙoƙiana amfani da su a kwance, karkatacciya, da tsarin isar da sako na tsaye, suna ba da ƙarfin da ake buƙata da dorewa don jure ƙaƙƙarfan ci gaba da aiki. A cikin wannan shafin yanar gizon, za mu bincika mahimmancin juriya na sarkar sawa a cikin tsarin jigilar kayayyaki da mahimman abubuwan da ke ba da gudummawa gare ta.

SCIC zagaye mahada karfe sarƙoƙian ƙera su da ƙarfe na CrNi, wanda aka sani da kyakkyawan ƙarfin jurewa da kaddarorin lalata. Sarƙoƙin suna yin aikin carburizing don haɓaka taurin saman su, tare da kewayon 57-63 HRC (Sikelin taurin Rockwell). Wannan babban matakin taurin yana tabbatar da cewa sarƙoƙi na iya jure wa ƙaƙƙarfan ƙarfi da sawa da ke da alaƙa da isar da kaya masu nauyi na tsawon lokaci.

Baya ga taurin saman, ainihin taurin sarƙoƙi yana da mahimmanci wajen tantance juriyar sa gaba ɗaya. An ƙera sarƙoƙin SCIC don samun ainihin taurin yanki na 40-45 HRC, yana ɗaukar ma'auni daidai tsakanin tauri da taurin. Wannan haɗe-haɗe na kaddarorin taurin yana ba da damar sarƙoƙi don tsayayya da nakasu da kiyaye amincin tsarin su a ƙarƙashin nau'ikan kaya daban-daban da yanayin aiki.

Zurfin carburizing na sarƙoƙi wani abu ne mai mahimmanci wanda ke tasiri juriya ga lalacewa. An tsara sarƙoƙin SCIC don samun zurfin carburizing har zuwa 2.5mm, tabbatar da cewa ƙaƙƙarfan Layer ya shimfiɗa zurfi cikin kayan. Wannan zurfin yana ba da gudummawa ga tsayin daka na sarƙoƙi, yana ba da shingen kariya daga lalacewa da kuma tsawaita rayuwar sabis.

Don tabbatar da taurin da sa juriya na sarƙoƙi, ana gudanar da gwaji mai ƙarfi don auna kadarorin su. An samar da rahoton gwajin taurin sarkar, yana ba da cikakken bayani game da takamaiman sigogi kamar taurin saman, taurin ainihin yanki, da zurfin carburizing. Wannan cikakken kimantawa yana ba da tabbacin ingancin sarƙoƙi da aiki, yana ba abokan ciniki kwarin gwiwa kan amincin su ga aikace-aikacen buƙatu.

Bugu da ƙari, kayan aiki da maganin zafi, ƙira da gina sarƙoƙi suna taka muhimmiyar rawa a cikin juriya na lalacewa. Ana amfani da igiyoyin sarkar da aka daidaita sosai, suna tabbatar da cewa kowace hanyar haɗi ta dace da ƙayyadaddun ƙayyadaddun bayanai don daidaito da daidaito. Wannan ingantaccen tsari na masana'antar da aka yi, musamman fa'idar aikace-aikacen aikace-aikacen da yawa inda daidaituwa yana da mahimmanci don kyakkyawan aiki.

Ingantacciyar ma'auni mai gudana na sarƙoƙi, tare da haɗin gwiwa tare da abubuwan haɗin gwiwa da ƙafafu, yana ƙara haɓaka juriyar su. An yi gyare-gyaren haɗin haɗin gwiwar a hankali don rage rikici da lalacewa, inganta ingantaccen watsa wutar lantarki da rage haɗarin gazawar da wuri. Wannan kulawa ga daki-daki a cikin ƙirar sarkar yana ba da gudummawa ga tsayin daka da amincinsa a cikin tsarin jigilar kayayyaki.

SCIC zagaye mahada karfe sarƙoƙidon tsarin jigilar kayayyaki ana samun su a cikin girma dabam dabam, gami da 16 x 64mm, 18 x 64mm, 22 x 86mm, 26 x 92mm, da 30 x 108mm, suna ba da abinci da yawa na buƙatun tsarin jigilar kaya. Ko ana amfani da shi wajen haƙar ma'adinai, siminti, ƙarfe, ko wasu masana'antu masu nauyi, waɗannan sarƙoƙi suna ba da juriya na musamman da kuma aiki, suna tabbatar da ayyukan sarrafa kayan da ba su yanke ba.

Juriyar lalacewa na sarƙoƙin ƙarfe na zagaye na haɗin gwiwa wani muhimmin al'amari ne na dacewarsu ga tsarin jigilar kaya. Ta hanyar haɗa babban taurin saman, ainihin taurin yanki, da zurfin carburizing, tare da ƙira da gwaji, sarƙoƙi na SCIC suna ba da tsayin daka na musamman da aminci a cikin buƙatar aikace-aikace. Lokacin da aka haɗa su tare da kulawa mai kyau da man shafawa, waɗannan sarƙoƙi za su iya ba da gudummawa ga aiki mara kyau da inganci na tsarin isar da sako, a ƙarshe suna cin gajiyar yawan aiki da ribar ayyukan masana'antu.

Lokacin aikawa: Fabrairu-28-2024