(1)Sarkar ɗagawa mai welded daraja 80WLL da index

Table 1: WLL tare da sarkar majajjawa kafa (s) kusurwa na 0 ° ~ 90 °

| Diamita na mahaɗin (mm) | Max.WLL | ||

| Kafa ɗaya t | 2-kafa t | 3 ko 4 kafa t | |

| 7.1 | 1.6 | 2.2 | 3.3 |

| 8.0 | 2.0 | 2.8 | 4.2 |

| 9.0 | 2.5 | 3.5 | 5.2 |

| 10.0 | 3.2 | 4.4 | 6.7 |

| 11.2 | 4.0 | 5.6 | 8.4 |

| 12.5 | 5.0 | 7.0 | 10.5 |

| 14.0 | 6.3 | 8.8 | 13.2 |

| 16.0 | 8.0 | 11.2 | 16.8 |

| 18.0 | 10.0 | 14.0 | 21.0 |

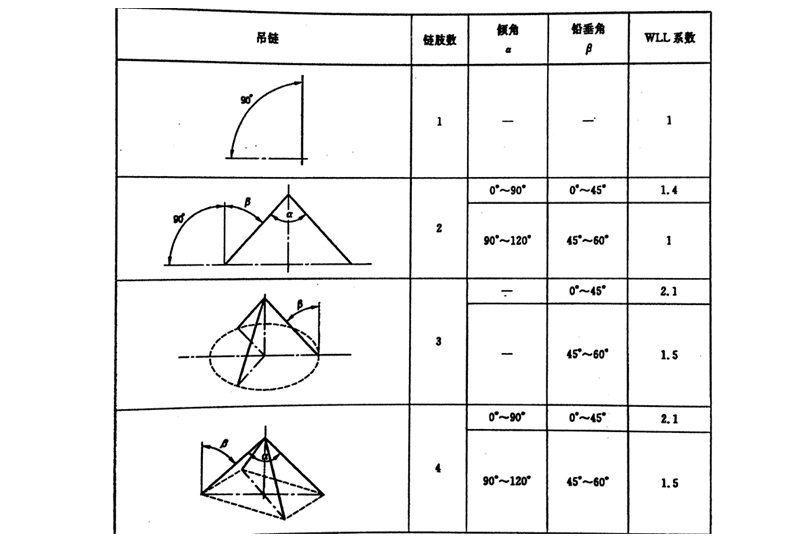

Table 2: WLL

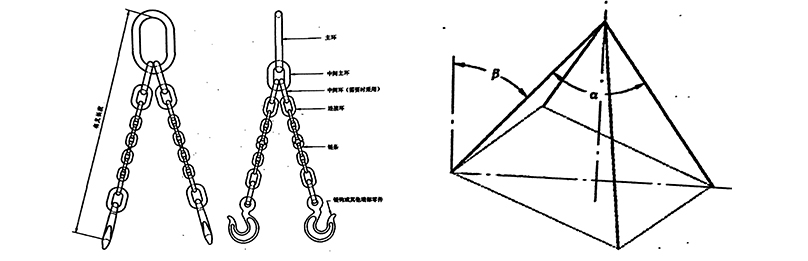

(2)sarkar majajjawairi da kusurwar kafafu

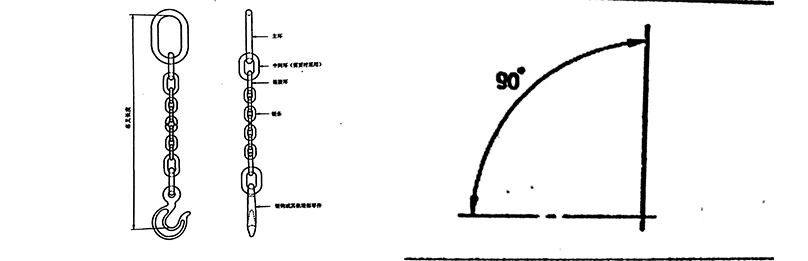

a.majajjawa sarkar kafa ɗaya

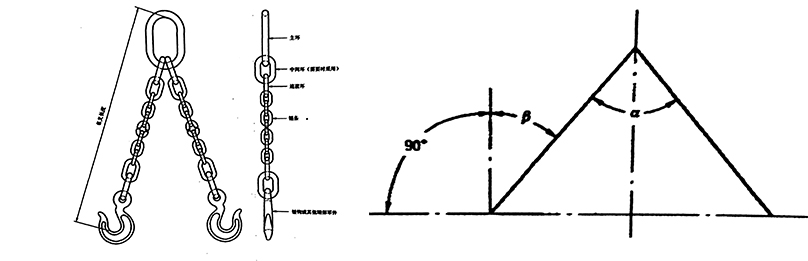

b.Sling sarkar kafa 2

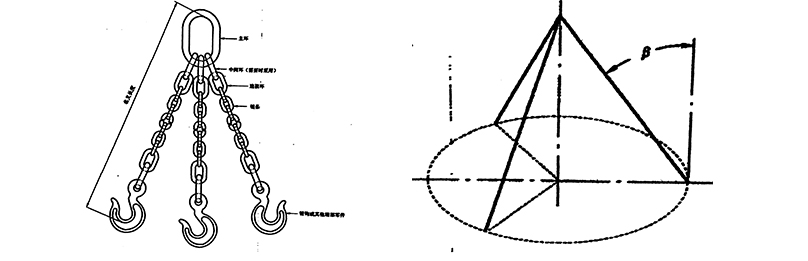

c.Sling sarkar kafa 3

d.majajjawa sarkar kafa 4

(3) dagawa zagaye mahada sarkar amfani

a.nauyin kaya zai zama daidai ko ƙasa da ɗaga sarkar majajjawa max.WLL.

b.lokacin amfani da majajjawar sarƙar sarƙar kafa 2 ko ƙafafu da yawa, babban kusurwar ƙafar majajjawa, ƙarancin nauyin da zai iya ɗagawa;kusurwar ƙafafu zai kasance ƙasa da 120° a kowane hali (watau kusurwar ƙafar sarkar tare da kusurwar gubar tsaye zai zama ƙasa da 60°).

c.Lokacin da aka ɗagawa a cikin bugun choker, nauyin zai zama ƙasa da 80% WLL.

d.Sarkar ɗagawa za ta kasance madaidaiciya ba tare da tsagewa ba, dunƙule ko lanƙwasa.Yi ƙoƙarin guje wa abubuwa masu nauyi suna birgima akan sarkar.

(1) dubawa kullum

a.Inspector, mita da rikodi

Ma'aikaci ko ma'aikacin da aka keɓe zai gudanar da binciken bayyani na yau da kullun akan sarkar ɗagawa kowace ranar aiki, kuma za a sami rikodin "nau'in binciken majajjawa yau da kullun" (duba Annex) a wurin, wanda ke nuna cewa ana iya amfani da majajja ta al'ada.

b.Duban gani

Bincika bayyanar da gani don alamun mummunan lalacewa, nakasawa ko lalacewa ta waje.Idan an sami lahani a cikin binciken, tabbatar ko za a iya sake amfani da ita bisa ga hanyar dubawa ta yau da kullun.

(2) Dubawa lokaci-lokaci

a.Inspector, mita da rikodi

Ma'aikatan da aka zaɓa za su gudanar da cikakken bincike akan sarkar bisa ga alamun lahani da aka tsara ta binciken yau da kullum, kuma su yi bayanai don tantance ko za a iya ci gaba da amfani da sarkar.

b.Duba maki

i) Ko alamun waje kamar alamar sarkar ɗagawa da nauyin aiki na ƙarshe sun fito fili;

ii) Ƙarƙashin Ƙarshen Ƙarshe na Ƙarshen Ƙarshe (Master Link, Intermediate Link, Connectors and hooks) na sarkar ɗagawa sun lalace, yanke da fashe, wanda ya wuce daidaitattun buƙatun kuma ba za a iya amfani da su ba;

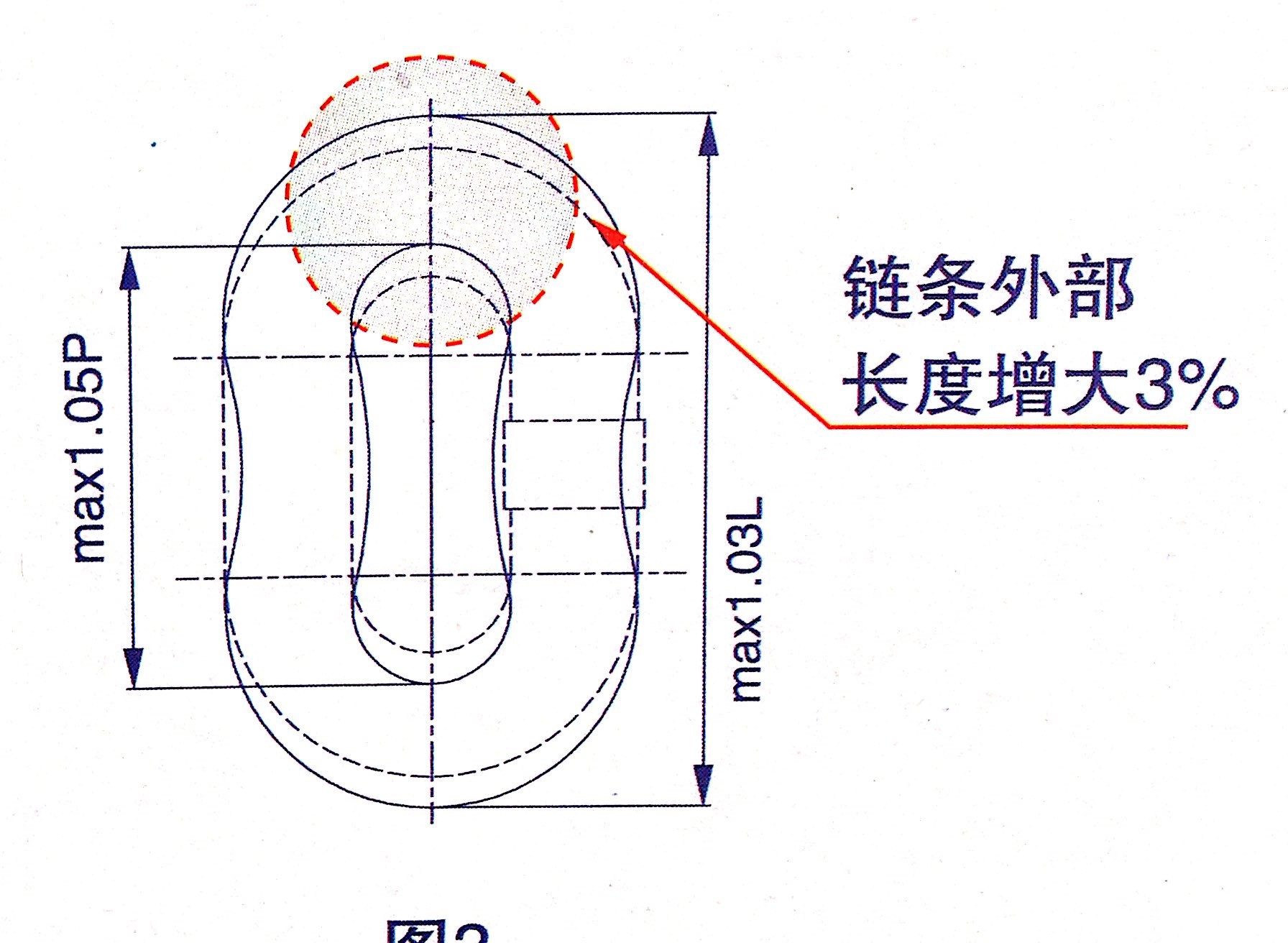

iii) Lalacewar hanyar haɗin yanar gizo: hanyar haɗin sarkar tana karkata, lanƙwasa da tsayi, kuma ba za a iya amfani da ita ba lokacin da ta wuce daidaitattun buƙatun;

iv) Rushewar haɗin gwiwa: daraja, daraja, gouge da lalacewa na hanyar haɗin gwiwa a waje na sashin madaidaiciya ba za a iya amfani da shi ba lokacin da ya wuce daidaitattun buƙatun;

v) Nakasar ƙugiya: nakasar "buɗe" da kuma murguda buɗaɗɗen ƙugiya sun wuce daidaitattun buƙatun kuma ba za a iya amfani da su ba;

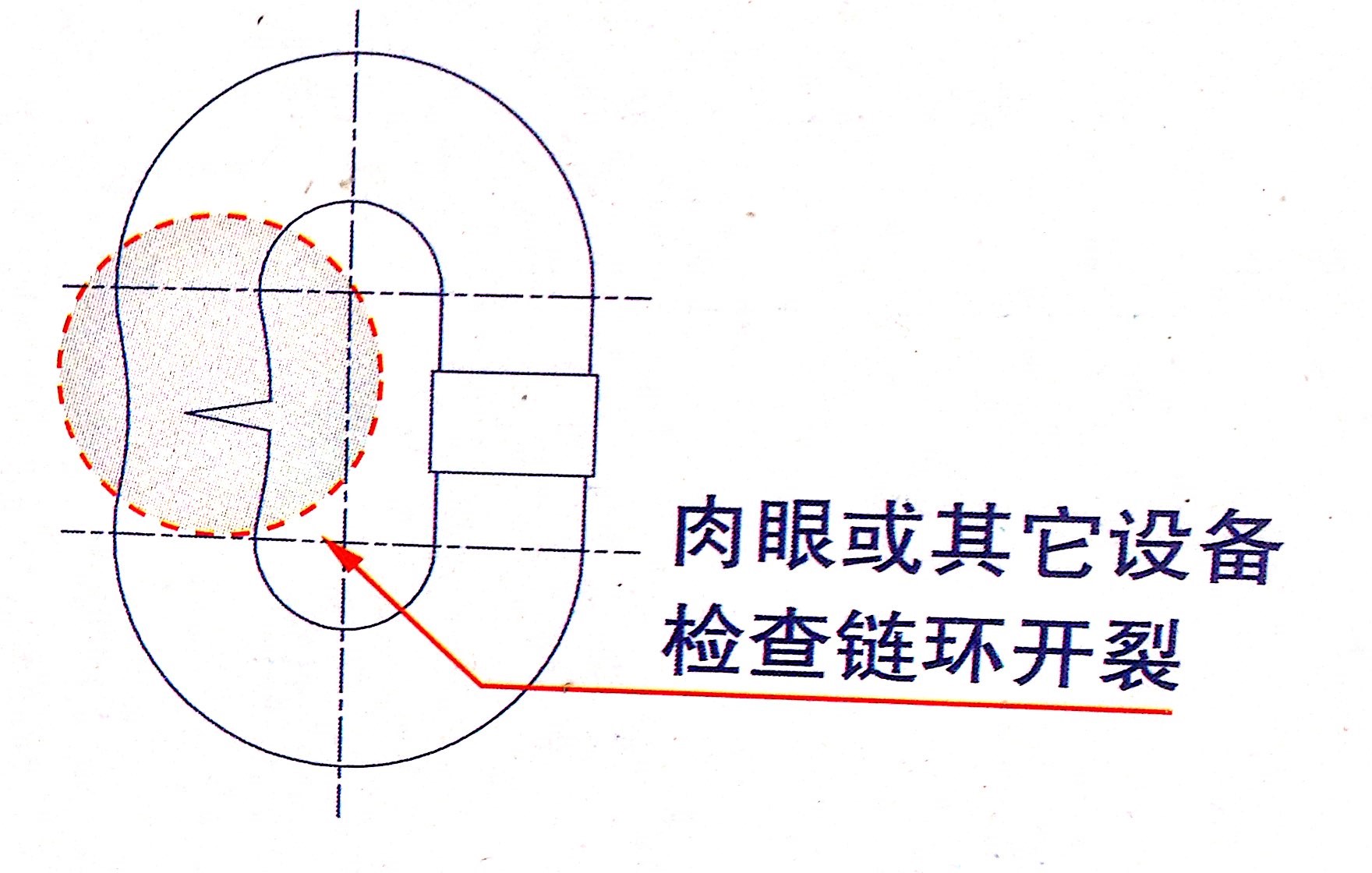

vi) Cracks: fasas da aka tabbatar ta hanyar kallo na gani ko NDT ba za a iya amfani da su ba.

a.nakasawa:

matsanancin tsawo elongation :3)

ciki tsawon elongation :5)

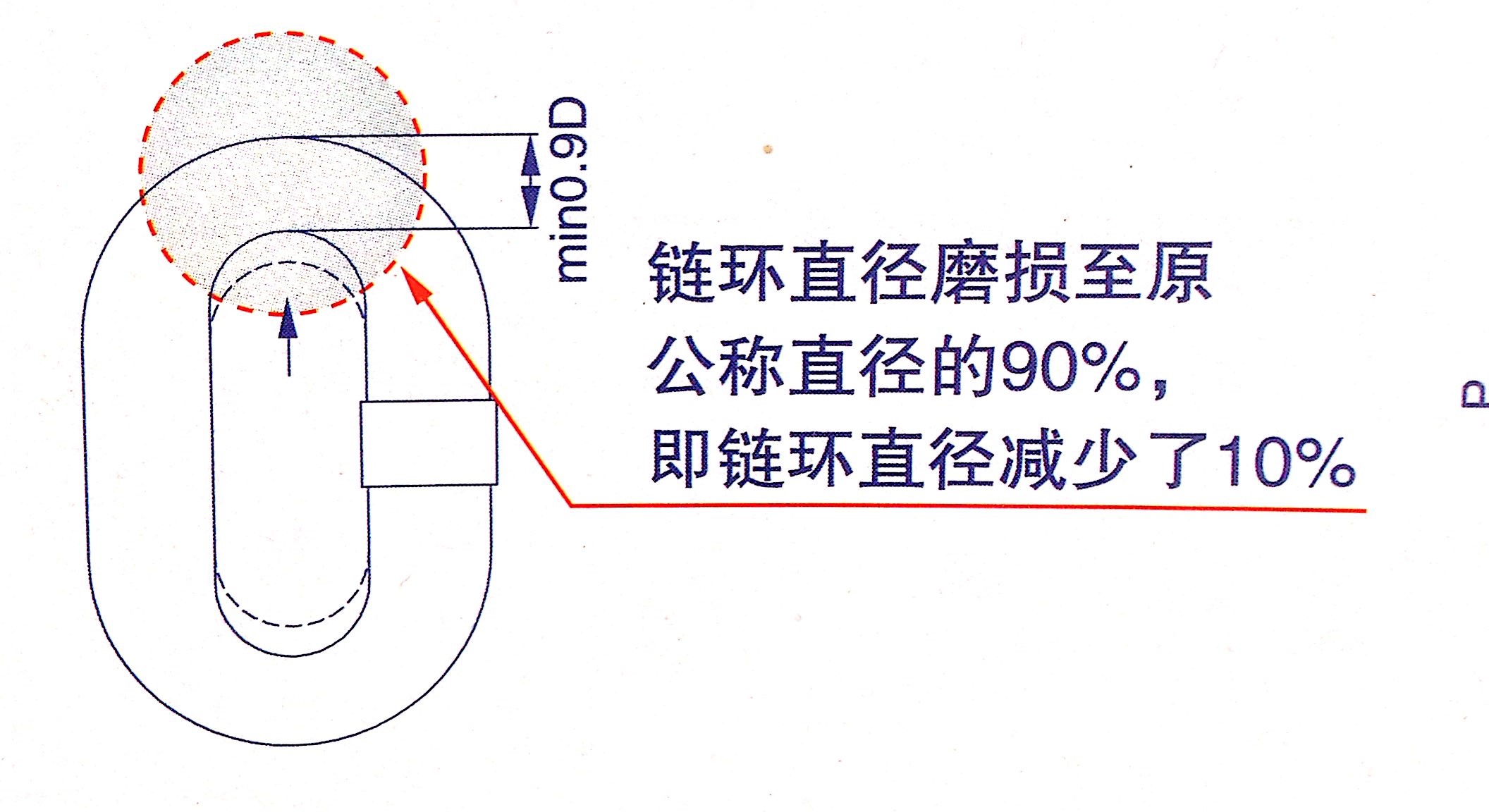

b.sawa:

hanyar haɗin giciye diamita bayan sawa bazai zama ƙasa da 10% ba (watau diamita <90% na ƙima)

c.fasa:

Ba a yarda da fashewa a saman hanyar haɗin yanar gizon ta hanyar dubawa na gani ko duba kayan aiki.

d.lankwasawa ko murdiya:

Babu bayyanannen lankwasa ko murdiya, mummunan lalata ko abin da ba za a iya cirewa ba da aka yarda don hanyar haɗin sarkar.

(2) kukku

a.Buɗe ƙugiya: haɓaka girman buɗe ƙugiya ba zai wuce 10% na ƙimar ƙima ba.

b.Sashe na damuwa (mai haɗari): ba za a rage kauri na sashin a wurin lalacewa da fiye da 5% ba.

c.Lalacewar nakasawa: karkatar da nakasar ƙugiya ba za ta wuce 5% ba.

d.Cracks: Ba a yarda da tsagewa a kan gabaɗayan ƙugiya ta hanyar dubawa ta gani ko duba kayan aiki.

e.Nicks da gouges: ana iya gyara su ta hanyar niƙa ko tattarawa.Filayen da aka gyara da kuma saman da ke kusa da su za su yi sauye-sauye cikin sauƙi ba tare da sauye-sauye na gaggawa a cikin sashin ba.Ba za a rage kauri na sashin gogewa da fiye da 5%.

(3) master link

a.Hargitsi: karkatar da haɗin gwiwar gaba ɗaya ba zai wuce 5%.

b.Wear: lalacewa na babban mahaɗin saman ba zai wuce 10% na ainihin diamita ba

c.Cracks: Ba a yarda da fasa a kan gabaɗayan mahaɗin mahaɗin ta hanyar dubawa na gani ko duba kayan aiki.

(4) sarkoki da sauran kayan haɗi

a.Buɗewa: Girman buɗewa na mari ya wuce 10% na ƙimar asali.

b.Sawa: ana sawa diamita na fil ko fil ɗin fil fiye da 10% na diamita na asali;lalacewa na sashin damuwa (mai haɗari) ya fi 5%

c.Crack: ba a yarda da fashewa a kan gabaɗayan kayan haɗi ta hanyar dubawa na gani ko duba kayan aiki.

(1) Hanyoyin haɗin sarƙoƙi na yau da kullun

(2) Nakasasshen ƙugiya (wanda aka goge)

(3) Lalacewa, lalacewa da ɓarkewar sarƙoƙi (scrapping)

(4) Lalacewar gida a saman mahaɗin sarkar (ana iya gyarawa)

(5) Hanyar haɗin sarkar ta ɗan sawa kuma ta lalace (za a iya ci gaba da amfani da ita)

Lokacin aikawa: Dec-17-2021